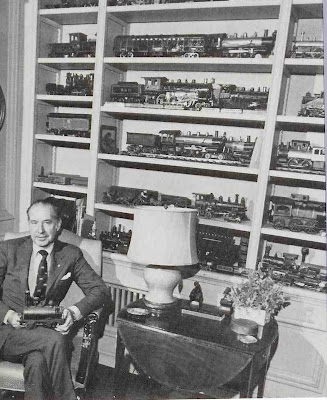

The below article was written by Robert C. Hendrich (above left) in the TTOS 1978 bulletin (John Trescott is the mold maker on the right):

"Several events culminated in this locomotive, which may seem unrelated, buth they all had a bearing on the ultimate outcome. It started with an old 42 and passenger cars, for which this nine-year old bought as a pile of sheet metal pieces for 25 cents in 1946! At last, a childhood ambition to have a Standard Gauge Train was realized! It was rebuilt and has been improved, added to, and run a lot in the succeeding years.

It came to our attention several years ago that other people also enjoyed these big trains and that there were many more treasures to be had in times past in this big size. Alas, many felt that it was rather a reckless attitude to even consider running anything since some old part was apt to break, never to be replaced and have something laid up for good. Such a shame, for the the fun was in watching this rumbling around the track, better yet, the track on a hardwood floor, to resound thru the whole house.

The years since saw many locomotives and cars scratchbuilt in several scales including live steam and career experience with casting and machined parts and their related manufacturing techiques. There came a kind of sudden inspiration several years ago to build a limited number of Standard Gauge engines which would fulfill several objectives. Namely:

1. It must be of absolutely first class construction, with large wearing surface to endure for generations and which no one would ever be afraid to run and run with no fear of wearing out or breaking anything.

2. It should be of a realistic proportion, much as O-72 did in O-gauge, thus combining prototype realism with Standard Gauge. (I guess we must confess that there was a long association with scale modeling by this time, if you hadn't guessed already.)

3. It must be able to negotiate regular track on the 42-inch circles that came with all Standard Gauge trains of the period (72-inch track was not out yet.)

4. There should be adequate power to pull a heavy train (By this time, realism was not a 3 or 4 car set from the catalogue but 15 or 20 cars in a heavy limited.)

On mentioning this desire and objectives a recurring thought was a GG-1, not from any catalogue either but from firsthand experience with the way these big locomotives would handle a train. And this gained from two years in the army stationed in Baltimore riding on military passes, more years ago than I care to remember but those machines endure to this day.

One night the basic engine was laid out on a drawing board and it really became an exciting program. The machinery was drawn on a 42 inch curve never losing sight of the need to run on this radius.

A chassis was made up and tried out. It indeed ran well and had power and control. Quiet and ran through s-curves, switches, pushing or pulling cars. Now for a body.....

The body proved to be a big hurdle. First just to make it and secondly to afford it. Some time was wasted trying for a fiberglass body but fortunately this proved impossible and we returned to metal which we felt all along was more in keeping with what we wanted this locomotive to be. The patterns for the trucks were straightforward and went well. The body was something else! Many times in the course of it's construction the pattern was taken to foundrys and information gained, the ideas were incorporated, more work, another visit.....

Finally we tried out a sample casting. It was just what we had hoped for! It finished up beautifully. Several more were made but this next batch was a disappointment. Nothing really wrong but the work had not been done with care and badly as we desired to push ahead, it was decided that this was just not up to our standard and they went back into the pot. The next group came out like we wished and were off.

Motors were the one area that were no problem. We had always planned to use commercial motors and ours have two field windings, twelve poles on the armature and spherical self-aligning bronze bushings on a quarter inch diameter ground steel shaft. The gears are industrial gears and we are sure may be obtained many years hence. The wheels and axles are turned from cold-rolled steel bar and it is just inconceivable ever running an engine enough to show any wear.

Of course while the work on the production locomotives was going on, the prototype was always one jump ahead and even without paint or details was run quite a bit. It too is now finished but has already run literally hundreds of hours and pulled as many as 26 cars, all we had or could borrow around the Gargraves track in the garage. This was a far cry from its first run which was over regular tinplate track, laid on the lawn. Only after the first run was it noticed that the gears were full of grass and weeds, the power never dropped off! It was however the first and last time it was on the lawn. Incidentally, nine cars were our maximum on the lawn since more would get pulled off the track on a curve.

The old 42 does not get run as much anymore since we now have a capable locomotive that takes all the car in sight and refuses to quit!"

I liked this article for a whole bunch of reasons, not the least of which is that it went through some of the nuts and bolts of making standard gauge. The more I read the more I want to make my own stuff. Who has one of these loco's? Can they make some video of it (I will do the editing and get it posted!). If two ingenius guys can make a prototypically accurate, workhorse locomotive in the 70's, why can't manufacturers with computer aided design and prototyping tools put something together like this now?In prior posts I had posted the advertisement for this wonderful loco. This is the follow up article I promised detailing where, why and so on. It's definitely an interesting picture into standard gauge history. By the way please note that I didn't write the above article. It was written by Robert C. Hendrich. I am just marveling at their ingenuity back in the 2oth Century.Marc

(from http://www.ironhorse129.com/rollingstock/CandS/dsp-passenger/nyelrail1.htm).

(from http://www.ironhorse129.com/rollingstock/CandS/dsp-passenger/nyelrail1.htm).  -Alex

-Alex